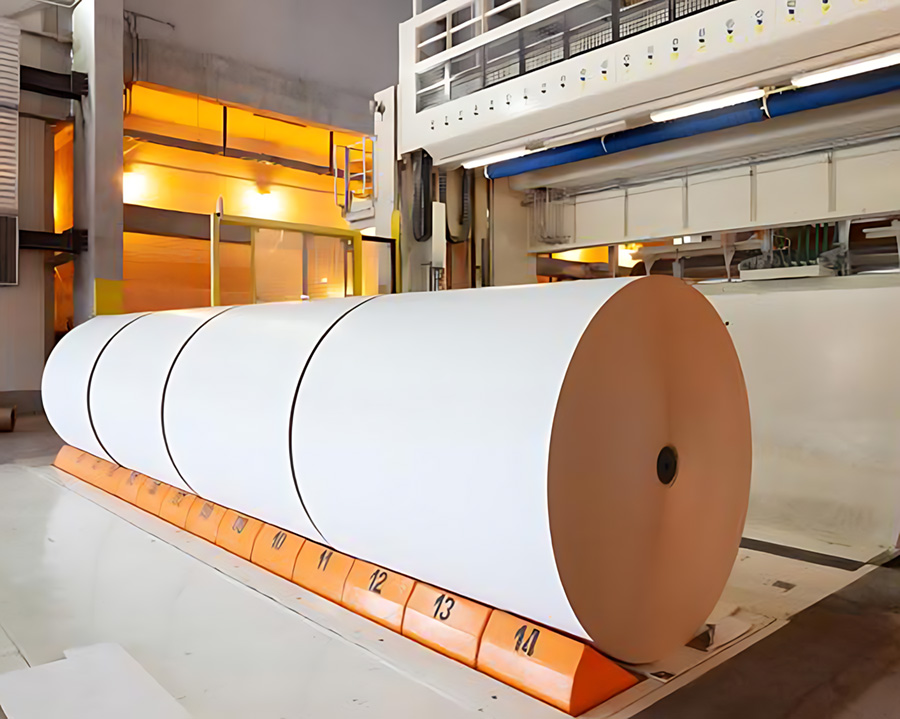

Pulp and paper bearings

Meeting the needs of a challenging industry

Market forces and increasingly stringent regulatory requirements make it more difficult than ever for pulp, paper and paper converting operations to be profitable. Competition is fierce and increasingly global. Energy and raw material costs remain high and rising, as do the costs associated with new health, safety and environmental legislation.

Paper mills are under unprecedented pressure to focus on process efficiency, machine reliability and all other factors that impact plant productivity and profitability, from training to information technology.

Pulp and paper solutions provide improved production efficiency and profitability. By combining expertise in bearings, seals, lubrication, mechatronics and services with many years of experience in pulping solutions and paper industry solutions, we provide paper mills with a range of solutions that boost production and reduce maintenance needs plan.

Offering solutions ranging from specialist bearings and seals to condition monitoring technology, maintenance tools, expert consultation and bonded reliability services, they help:

Increase production

Reduce downtime

Reduce maintenance costs

Reduce energy consumption and consumable losses

Improve worker safety

Upgrade or optimize equipment

Minimize capital expenditures

Wind power generation main bearing belongs to the field of wind power generators. The characteristics are: main bearing upper outer ring, main bearing lower outer ring, thrust cylindrical rollers, cage, main bearing inner ring. There are two rows of thrus

More

There are many types of aircraft bearings. In response to customer demands for reduced weight, reduced environmental pollution and high performance from bearings, bearing systems have become more complex and require greater reliability and quality control

More

Gear units and transmission systems operate in almost every industrial process and are available in every possible shape and size, so they face a wide range of operating requirements and conditions. But regardless of the industry or application, all indus

More

As a clean energy source that does not produce carbon dioxide that contributes to the greenhouse effect, wind power is rapidly spreading around the world. Large wind turbines (windmills) are giant machines. Many 2MW wind power equipment currently under co

More