The places where mining machinery and engineering machinery are active are mostly mining sites in mountainous areas and desert areas that are far away from ordinary human life. Sometimes they even work 2,000 meters underground. There are many types of such machinery, from mineral crushing machinery to cutting machinery, screening machinery, loading machinery, conveying machinery, etc., all of which are equipment that operates continuously 24 hours a day. If any of these machines breaks down, it will have a great impact on production at the mining site. Moreover, the recent increase in the size of machines has made maintenance work very difficult.

Therefore, in terms of the environment in which bearings are used, there are many conditions that are very harsh on bearings, such as "heavy load + impact load", "light load + high-speed rotation", "heavy load + low-speed rotation", etc. Therefore, users desire bearings that are robust, durable and highly reliable that can withstand these harsh working conditions. In order to meet these needs of users, we have been integrating material technology, lubrication technology, analytical technology and more advanced bearing design technology to contribute to customers improving production efficiency and reducing maintenance costs at mining sites in harsh environments.

The railway locomotive and vehicle axle system adopts different structural design due to different application conditions. The locomotive and passenger car have axle box, and the bearing is connected with the bogie through the axle box. The railway freigh

More

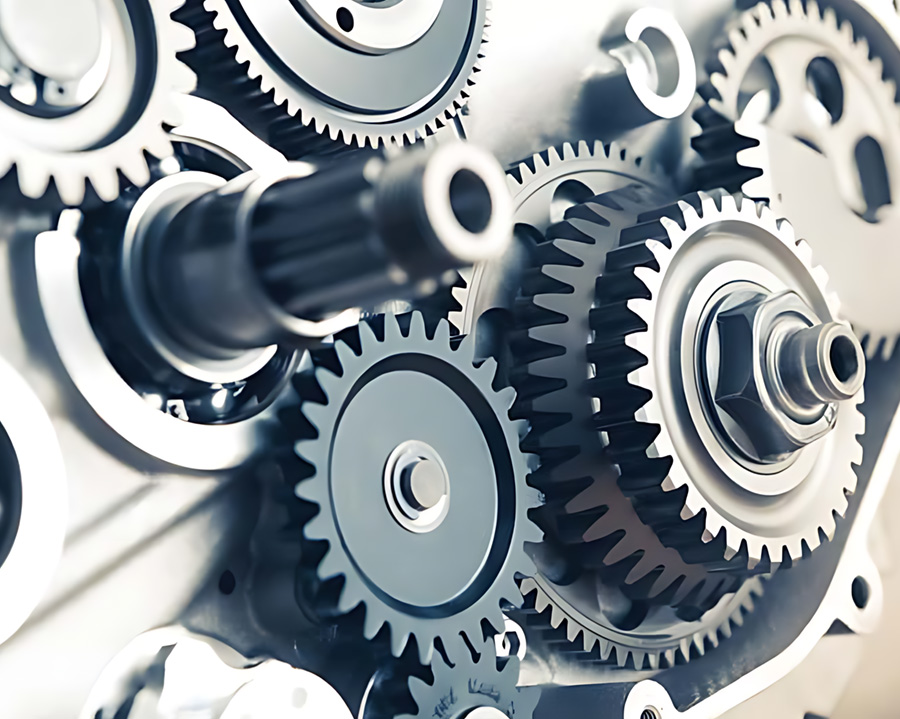

Gear units and transmission systems operate in almost every industrial process and are available in every possible shape and size, so they face a wide range of operating requirements and conditions. But regardless of the industry or application, all indus

More

Powder metallurgy bearings are made of metal powder and other anti-friction material powders that are pressed, sintered, shaped and immersed in oil. They have a porous structure. After being soaked in hot oil, the pores are filled with lubricating oil. Du

More

Motor bearings, also known as motor bearings or motor bearings, are special bearings specially used on electric motors or motors. The bearing used in the motor is a part that supports the shaft. It can guide the rotation of the shaft and can also bear the

More